- Products

Accessories

Peripheral Systems

- Service

- Applications

- Company

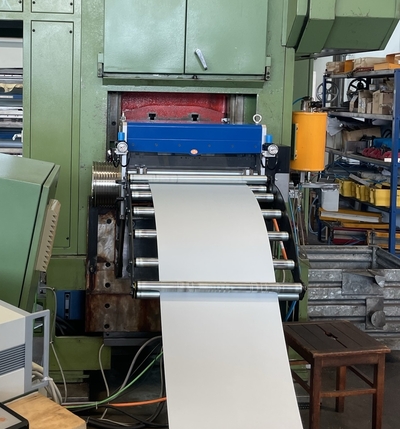

Bergmann-Hillebrand mainly produces from the coil perforated sheets up to 1 mm thick, in particular precision perforated sheets with small hole widths and high throughputs. High feed accuracy is essential here, as inaccuracies are directly visible in the final product and the products are often used as visible parts. High-quality speaker covers for the automotive sector are a speciality.

The existing electro-hydraulic feeds in production do not seem to be up to the current and future requirements. Feeders of different concepts and manufacturers have already been tested, but the tests did not give the required results. The recommendation of a feeder specialist was to investigate the use of an electronic feeder with a torque motor from Zehnder & Sommer.

Zehnder & Sommer proposed an EV XF 640 TQ to Bergmann-Hillebrand as a solution due to the large material widths, high material weight and load variations in the loop, as well as the high accuracy requirements. The device generates a permanent feed accuracy of +/-0.02 mm and can withstand material load variations due to the holding force of the torque motor and the contact pressure. In addition, the device is equipped with two individually adjustable pressure cylinders, which counteract a saber-shaped material flow.

This new acquisition has reduced the complexity of the entire feeding concept. Thanks to the reduced power consumption, the energy efficiency of the entire stamping installation is increased. Thanks to the components used, the simple construction and the overall concept, service and maintenance are easier and secure the path to the future.

With the experience gained within six months, the customer is convinced that the concept is suitable for replacing other existing systems.